With HighLine XM Screening & Satin Screening

If you have ever seen the new high definition televisions sitting beside the regular CRT displays you can immediatly see the difference. Not only are the images cleaner & sharper, they are also more colorful and vibrant. We get these same improvements with our High Definition Printing. Why settle for regular printing when you can amaze your customers with High Definition Printing? High Definition Printing will seperate you from the competition giving you the edge you need to win & keep those jobs. No one else offers High Definition Printing at trade prices.

What is High Definition Printing?

High Definition Printing is essentially printing with very high resolution resulting in lifelike images with detail & clarity that you just cannot achieve with traditional printing. This concept is similar to that of High Definition Television. In a world that is seeing quality advancements in almost everything that we see (such as TV's, cameras, printers, etc.), it only makes sence that print quality should be improved as well. The technology to improve print quality has existed for over 10 years now & with new technology, it only gets easier & easier. Advance printing has been printing with High Definition Screening since 1999.

Since we are talking about visual representation, the best way to explain this is to show the difference. The babies face (right) was printed with different screening. The images were then scanned at 4800 dpi & enlarged to show the dot structure. Below are the result with the different screenings. As you can see, the 150 line (far right below) image shows large dots & the image is not recognisable. With all the other screens, you can clearly see babies eye as well as other fine detail.

Stochastic Screening 10 Micron |

Stochastic Screening 20 Micron |

HighLine Screening 376 Line |

HighLine Screening 308 Line * |

Conventional 150 line |

High Definition Screening in the market

Advance Printing was the first printer to switch entirely to stochastic back in 99. There were other printers using it at the time however, they ran less than 5% of their work with this screening. Since then, there are now over 100 Canadian printers offering linescreens above 200 line & many more who now print 175 or 200 line.

HighLine XM Screening

Advance Printing has upgraded to HighLine XM screening from Esko. We will still image FM screening with either Satin screening (from Heidelberg) or Monet (from Esko). HighLine screening is a hybrid sceening that gives an image similar to that of stochastic, but without the technical difficulties. The main difference you will see with the new screening is the smoothness of the fleshtones and flat tints. With stochastic screening these areas appeared slightly grainy however that has pretty much been eliminated with HighLine Screening. HighLine is also much more stable on the plate, giving more stable colour reproduction from beginning to end of the run. Here are some other reasons for using high definition printing:

Why switch to HighLine?

Since we are open to improvement, we are not emotionally stuck on any product. Printing with stochastic does create some challenges & it does have it's drawbacks. 10um printing is the biggest challenge due to the size of the dot. Most of the printing plates on the market are not capable of holding the small dots. Highlight dots are the hardest to hold & the dot tends to slowly disappear from the plate. The plates also have a difficult time consistantly imaging the dots, resulting in dot gains that vary as much as 15%. There is also an issue with some plates that produce banding in flat tints. 20um printing is much easier to control since the dot is twice the size. It does not totally resolve the problems but it is far more reliable than 10um. HighLine is a hybrid screening that brings together the best of both worlds with the benefits of stochastic & the stability of a larger dot.

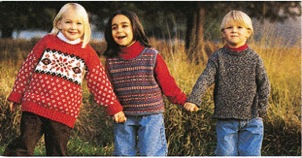

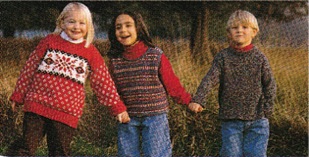

Compare the print results yourself

Printed with: Stochastic Screening 10 micron

|

Printed with: Conventional 150 line

|

Print Quality

Printing at the standard 150 line screen results in an image with rosettes, loss of detail and moire. Many copiers and printers have improved in quality and are looking as good as traditional 150 line screen using screening technology similar to stochastic. The technology exists to improve print quality so why not use it.

Why not use a higher linescreen such as 175 or 200 line?

While 175 line looks a little better it is only a small step, 200 line would be preferable over 175. Both of these resolutions should be imaged at a higher resolution, 3360 DPI (although you could get away with imaging 175 line at 2540 DPI) which result in increased ripping time and substantially increased imaging time which means extra costs. High Definition images at 2540 DPI, ripping time is the same as 150 line and any extra imaging time is minimal.

File size

The vast majority of files are produced at 300 DPI and these files would not be suitable for the higher line screens. Files for 175 line should be scanned at 350 DPI and 200 at 400 DPI which result in file sizes that are 35-55% larger. This would increase the time it takes at every production stage, increase the storage space needed for these files and increase network transfer times. This would result in extra costs for everyone. High Definition screening utilizes 300 DPI images and lower resolutions are possible without degrading print quality.

Improved quality without increasing costs

The dot structure of the high definition screening results in an image that looks close to continuous tone without any changes to current workflows. Fine detail is visible even when using a loupe. Rosettes and moire are eliminated and screen tints look smoother.

Printability

High Definition screening also allows us to carry thinner ink films, which means that jobs dry faster. Its also more stable on press reducing color shift and mis-registration is less noticable.

Hexachrome

Hexachrome is a 6 colour printing process which substantially increases the colour gamut over what is capable with 4 colour process. Printing in high definition eliminates the problems of additional screen angles for these extra two colours.

About Stochastic screening

Stochastic Screening came onto the market many years ago (before Computer to plate technology) and since it was used in film based workflows it had many problems. The size of the dot was so small that most conventional plates had a problem reproducing that dot. There was also no proofing system that would reproduce dots that small. Due to those factors stochastic screening did not gain acceptance in the printing industry and hardly anyone used it.

CTP and the new thermal plates have changed all that and solved all of the problems associated with the transfer of image to plate and digital proofing has solved the proofing problem. The laser in our trendsetter produces a 21 micron dot which the thermal plates have no problem holding consistently. The dots are all the same size so for a darker tint there would be more dots, in traditional screening the location of the dot stays the same but the size of the dot gets bigger for a darker tint.

Diamond Screening & Satin Screening, which are Heidelberg's brand names for stochastic screening, is the equivalent of printing a 400 or 500 line screen. With the elimination of line screen and screen angles we are able to reproduce finer images and lines or straight edges that used to appear jagged now print smoothly. High Definition also eliminates the pattern related to screen angles known as rosettes.